Constant lubrication of cable cars thanks to simalube

Maintenance work often takes place outdoors - on supports metres high - which is a difficult task for maintenance technicians. Extreme conditions such as frost, snow, dirt and moisture make it particularly difficult for cable cars and mountain railways to function smoothly. A continuous supply of lubrication points is therefore essential. Without regular maintenance, mechanical parts wear out quickly. As a result, considerable malfunctions and downtime can occur, leading to costly repair and maintenance work.

Lubrication points

Challenges

- Strong temperature fluctuations make lubrication and the service life of cable car systems more difficult

- Manual lubrication is time-consuming, as the lubrication points can only be reached with great effort

- Long operating times reduce the time available for regular maintenance

- Wear on the coupling, track and guide rollers often leads to cost-intensive maintenance work

- Manual lubrication at lubrication points that are difficult to access, e.g. at lofty heights, increases the risk of accidents and jeopardises occupational safety

Solution

- simatec offers years of practical experience with customised special solutions with the simalube lubricator

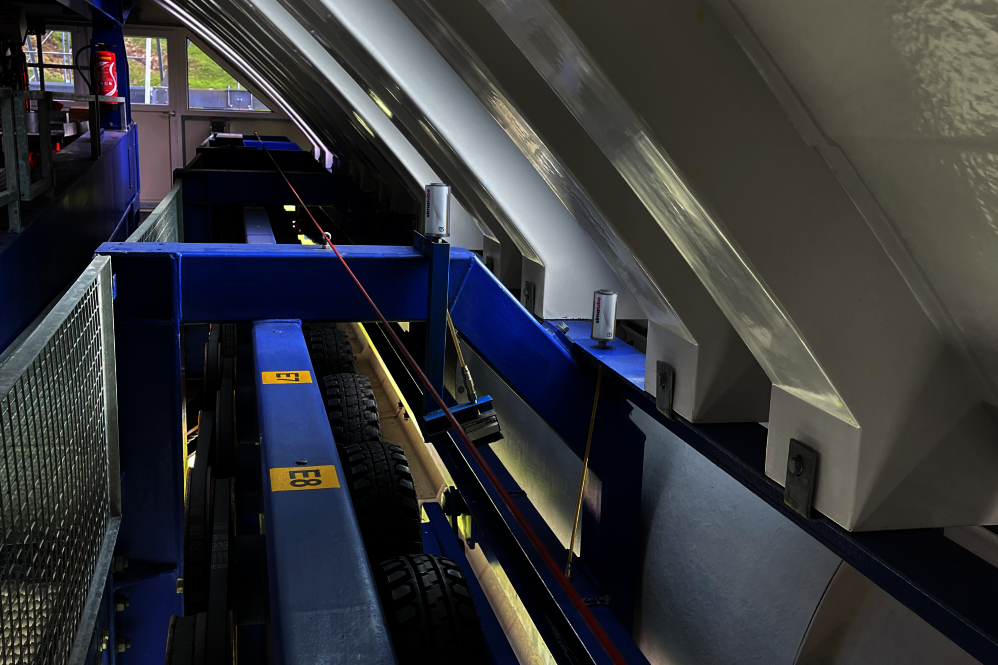

- simalube ensures constant lubrication even at extreme temperatures and thus extends the service life of the systems

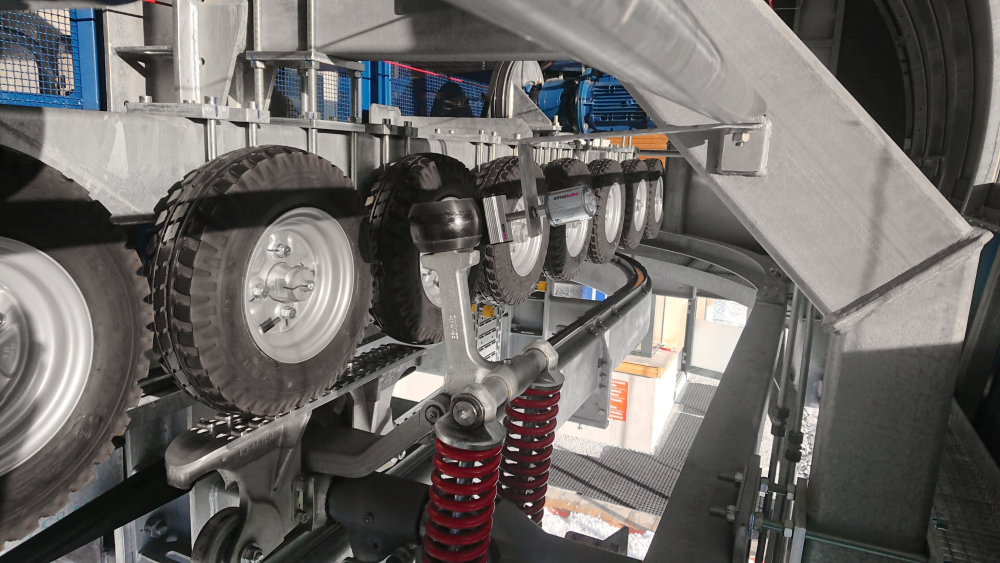

- Assembly parts designed specifically for cable car applications enable automatic lubrication in hard-to-reach areas and facilitate maintenance

- simalube minimises the need for manual relubrication and thus reduces the time required

- Continuous lubrication with simalube reduces wear and extends the service life of the coupling, track and guide rollers

- simalube increases occupational safety and minimises the risk of accidents at work

Areas of application and advantages

simalube applications on cablecars and mountain railways

- Suspension rope guides

- Coupling rollers, track rollers and guide rollers

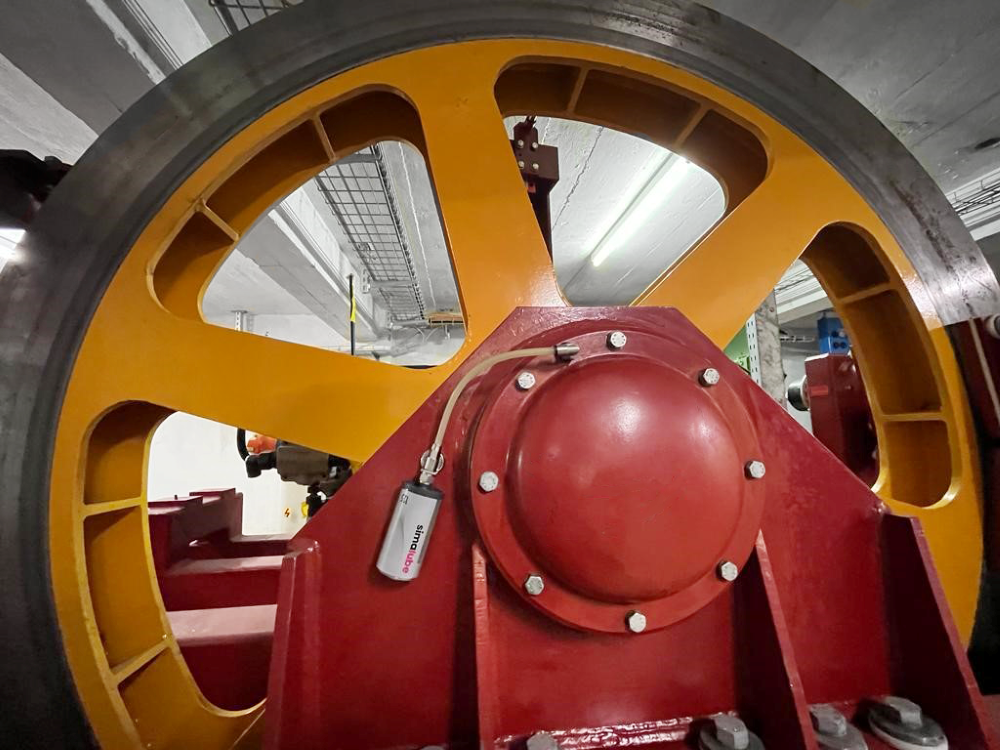

- Drive and deflection pulleys

- Load cable pulleys

- Drive motors

- Cabin doors

- Aggregates and electric motors (e.g. snow-making systems)

Advantages of the simalube lubrication system

- Optimised inspection rounds, as only a visual check of the lubrication is required

- Improved occupational safety, as lubrication is no longer necessary during operation of the system

- simalube lubricators can be filled with the customer's preferred lubricant

- Continuous lubricant delivery guaranteed even with strong temperature fluctuations

- Optimisation of maintenance costs thanks to reduced lubricant consumption and less time required

- Longer service life of the systems thanks to continuous lubrication

Videos

More simatec products for you?

Innovative maintenance products for rolling bearings simplify complex processes and reduce the maintenance effort on tens of thousands of machines around the globe. You can also benefit from our heating devices and special tools for the perfect handling of rolling bearings.

simalube

Accessories

With the range of accessories, the simalube is easy to install anywhere and in any position.

simatherm

Induction Heater

Perfect solution for fast, thermal mounting of rolling bearings.